Novel seed crystal paving method during cast single crystal production

A laying method and seed crystal technology, which are applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of the quality decline of cast single crystals, the generation of dislocations and proliferation of seed crystals, etc., so as to improve the quality and reduce the dislocation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

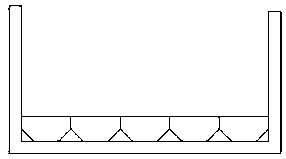

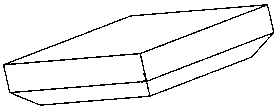

[0034] Such as figure 1 , figure 2 As shown, when producing cast single crystals, a new seed crystal and its laying method are provided, including the following steps:

[0035] Step a: straight pull the single crystal rod to remove the edge skin, and then cut it to obtain a small cuboid-shaped seed crystal with a size of 156mm×156mm×30mm;

[0036] Step b: chamfering the four sides of the cuboid-shaped seed crystal in contact with the bottom of the crucible, the angle is 45°, and the height is 15mm;

[0037] Step c: The sides of the seed crystals are closely attached to cover the entire bottom of the crucible to form a complete seed crystal layer.

[0038] The complete seed crystal layer described in step c is formed by splicing 25 seed crystals.

Embodiment 2

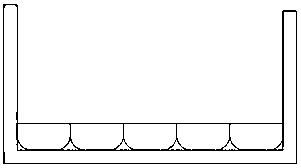

[0040] Such as image 3 , Figure 4 As shown, when producing cast single crystals, a new seed crystal and its laying method are provided, including the following steps:

[0041] Step a: straight pull the single crystal rod to remove the edge skin, and then cut it to obtain a small cuboid-shaped seed crystal with a size of 156mm×156mm×30mm;

[0042] In step b, the four sides of the cuboid-shaped seed crystal in contact with the bottom of the crucible are rounded, and the radius of the rounded corners is 15mm;

[0043] Step c: The sides of the seed crystals are closely attached to cover the entire bottom of the crucible to form a complete seed crystal layer.

[0044] The complete seed crystal layer described in step c is formed by splicing 25 seed crystals.

Embodiment 3

[0046] Such as Figure 5 , Image 6 As shown, when producing cast single crystals, a new seed crystal and its laying method are provided, including the following steps:

[0047] Step a: straight pull the single crystal rod to remove the edge skin, and then cut it to obtain a small cuboid-shaped seed crystal with a size of 156mm×156mm×30mm;

[0048] In step b, the seed crystal is further processed into a step shape, and the height of the step is 15 mm;

[0049] Step c: The sides of the seed crystals are closely attached to cover the entire bottom of the crucible to form a complete seed crystal layer.

[0050] The complete seed crystal layer described in step c is formed by splicing 25 seed crystals.

[0051] Fig. 7 is the minority carrier lifetime test diagram of cast single crystal obtained by adopting the conventional seed crystal laying method, and Fig. 8 is the minority carrier lifetime test diagram of cast single crystal obtained by adopting the new seed crystal and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com